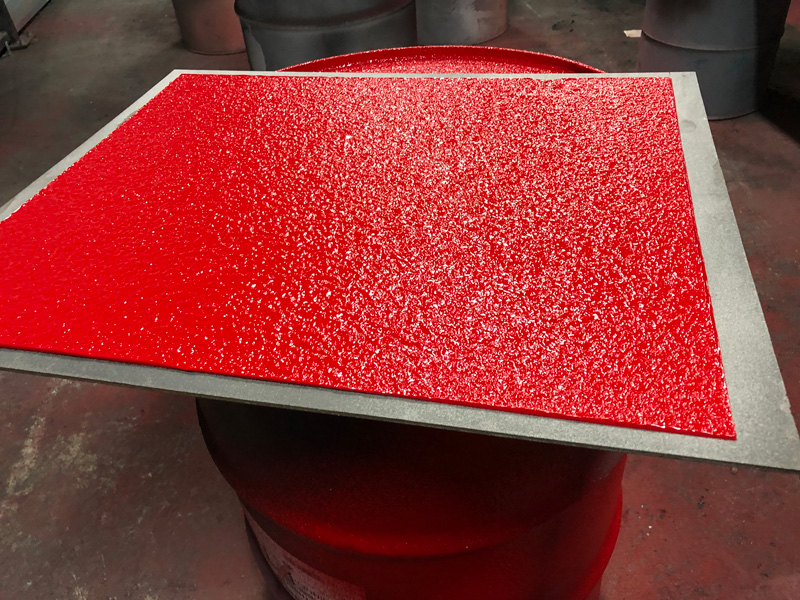

Non-Slip Coatings

Non-Slip Coating, Wear & Abrasion Resistant Coating

CCMP are licensed applicators of Speedliner, a low VOC thick polymer (92 shore A hardness) coating with tensile strength (up to 7500psi) and super high abrasive wear resistance.

This is an ideal product for mining and marine applications. The coating is super hard wearing, impact resistant, with the ability to be textured using specialised techniques to provide a non-slip coating to Australian standards. The coating is also food grade rated.

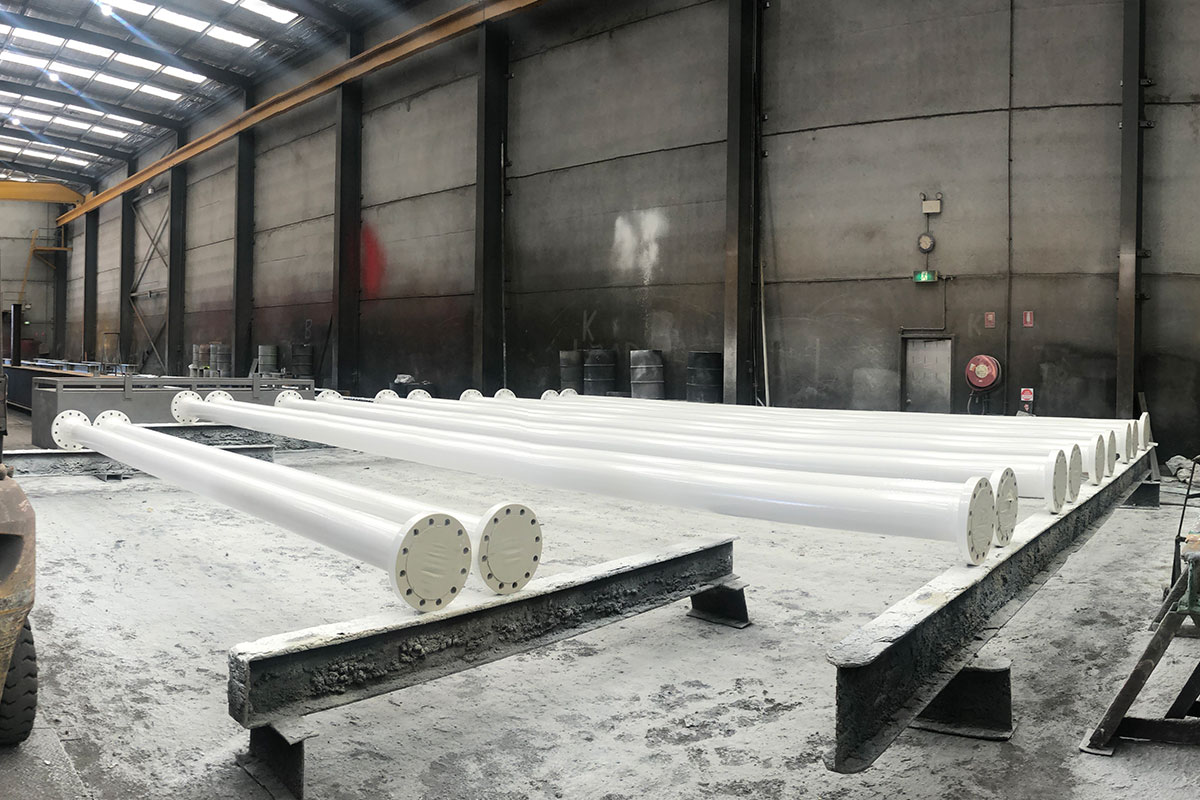

NON-SLIP, ABRASION RESISTANT COATING FACILITIES

Our workshop less than 45 Minutes from Sydney & Newcastle metro areas

- We can transport your material to our facility

- Our factory is over 3500 sqm (2 Workshops)

- Overhead crane capacity to 20 Tonnes. (Heavy lifts over 20 Tonnes are managed by use of load mobile crane companies)

- Significant lay down area for coating application indoors within both workshops

- Fleet of forklifts up to 10 Tonne capacity service the yard area.

- YARD: Fully concreted area (over 4000 sqm) for storage of incoming/outgoing goods and to minimise dust.

- CCMP’s experienced site applicators are also able to carry out protective coatings out in the field and on your project

Got a question? We welcome your enquiries, call now.

Why choose CCMP for Non-Slip, Wear and Abrasion Resistant Coatings?

CCMP is one of a few companies that has the capacity for the application of Abrasion Resistant Coatings along with the steel substrate abrasive blasting preparation – all at the one site.

- Collect your steel structure or product in one of our fleet of trucks and prime movers,

- Prepare the surfaces for abrasive blasting, industrial spray painting, protective metal coating and abrasive blasting/sandblasting processes in Sydney, Newcastle and wider NSW in-house and in accordance with your specifications, and

- Deliver your renewed and protected steel structure or product back to you.

- Service any project (industrial or domestic), no matter how big, small or complex.

Once we have carried out sandblasting in Sydney or wider NSW, the exposed ‘raw’ steel is highly subject to immediate rust, even in transit. The benefit of having the abrasive blasting and protective metal coating completed at the one site is therefore advantageous. As general rule of thumb, protective coating must be applied to steel within 4 hours of blasting.